Influence of flow controllers on ultrasonic flowmeters

The operating principle of an ultrasonic flowmeter is based on the use of sound waves. This means that this type of flow meter is sensitive to sonic disturbances. In any measurement environment there will always be some form of sonic noise. Up to a certain point this is not a problem. When does it become a problem?

Signal-to-Noise Ratio

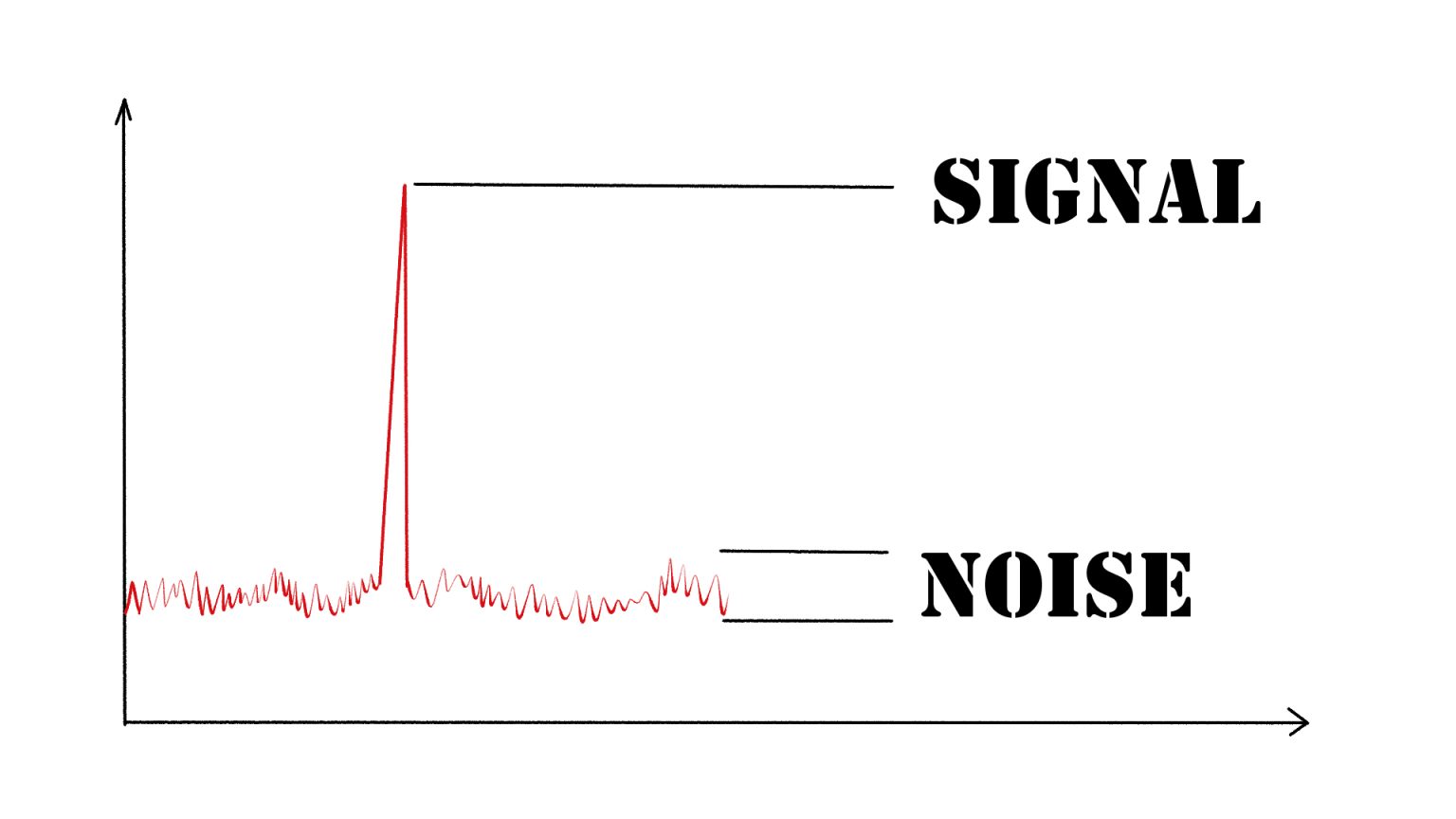

When the disturbing noise in the environment of the ultrasonic flowmeter approaches the sonic waves generated by the meter, the receiving transducer can no longer distinguish the measurement signal from the noise. At that point, the signal-to-noise ratio (S/N) is too poor.

But too much incoming noise is not the whole story. Noise actually only becomes a problem for a measurement when its frequency is close to the carrier of the ultrasonic flowmeter. Other frequencies are filtered out by the receiving transducers.

Spectrum analyzers can measure the power level across the frequency spectrum and make this problem clearly visible.

Illustration: fictitious measurement result on a spectrum analyser with a good signal to noise ratio (S/N).

A remarkable and often misunderstood concept now becomes clear: the sound we humans can hear is not noise to an ultrasonic flowmeter. And the noise an ultrasonic flowmeter measures is inaudible to us. In principle the source of the disturbance can be anything, but in practice valves and regulators are often the biggest source of pollution. Due to the flow, parts can vibrate in their own frequency and thus produce noise. The amount of disturbing noise therefore also depends on the flow velocity.

How regulators with built-in silencers can be a problem

Regulators can be optimized to produce less noise and the main reason for this is to give our ears some peace of mind! So although these silenced regulators produce up to 20dB less noise for humans, they can produce a lot of extra noise in the frequency spectrum of the ultrasonic flow meter. If you are considering including a silenced regulator in your design, ask your supplier for a frequency response graph. This shows how much noise a regulator makes over a frequency range at a given pressure, flow rate and temperature.

But the problem of sonic noise is not limited to pressure regulators with silencers. Noise must be taken into account in the design of a system and must be defensively designed. But how?

Designing a successful measurement setup

Based on our experience, different construction methods and installation instructions have proven to reduce noise.

- Add one or two bends between the regulator and the flowmeter.

- Maximize the distance between the regulator and the flowmeter.

- As mentioned, a regulator or valve with a built-in silencer can be problematic.

- Use a flow conditioner as a damping element (S/N 6dB better).

- Use a special damping element (S/N 20dB better).

- Add tees between regulator and meter.

Elbows and tees are the classic way to attenuate noise, but don't forget that this also distorts the flow profile. And flow profile sensitivity is just another weakness of an ultrasonic flowmeter. A straight feed of at least 10D should solve most flow profile problems. Even if it is a 4-path meter.

Don't expect big differences between upstream and downstream placement of the flow meter. Sound travels in every direction and a pipe is an excellent conductor for sound.

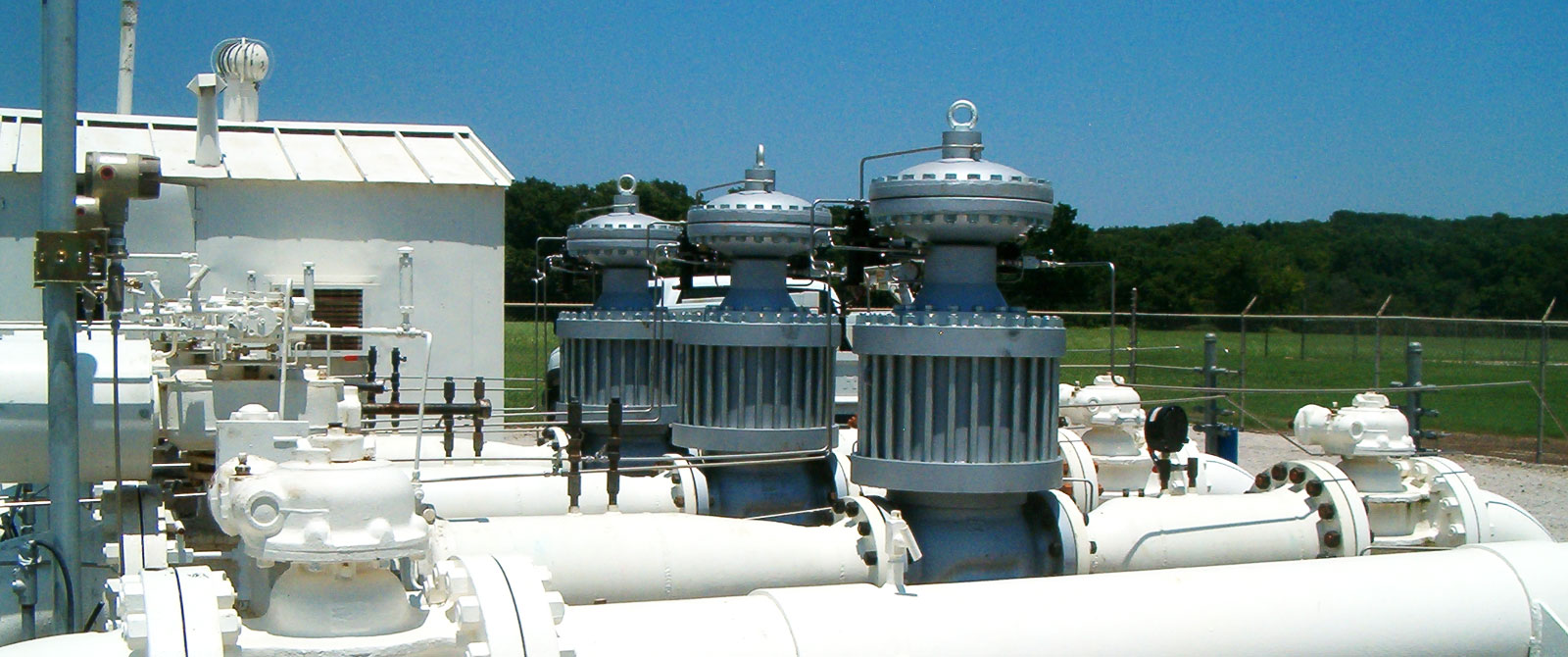

Photo: Traditional sound attenuation with T-pieces.

Photo: silencer for ultrasonic flowmeters.

Tips for choosing an ultrasonic flowmeter

It is a good idea to already consider a number of factors when selecting the ultrasonic flow meter, in order to minimize future problems with sonic noise:

- Transducers must provide a high signal level.

- Good frequency filtering.

- A meter with a direct path is better than an indirect one.

- Switchable carrier frequencies (S/N 10dB better).

- Phase correlated signal processing.

- Digital packages provide checksum error checking.

Phase correlated signal processing: this means that the receiver "knows" what to expect and only amplifies phase correlated signals. Signals with the same frequency, but with a zero crossing at another time are filtered out.

Digital packets with checksum error checking: the computer "knows" which bits to expect. If the incoming signal is not the same as what was transmitted, the signal is assumed to be noise. The disadvantage is that these calculations take time and have a negative effect on the response time of the meters.

A practical guide to solving measurement problems

When trying to improve the measurement results of an ultrasonic flow meter in a sonically contaminated environment, these are the sequential steps you might take:

- Change carrier frequency or transducer to a (often higher) frequency.

- Activate signal averaging (find a compromise between signal-to-noise ratio and dynamic behaviour).

- Increase noise attenuation with an additional attenuator plate or flow controller.

- Place meter and controller further apart.

The conclusion of all this must be: the use of an ultrasonic flow meter in the vicinity of a regulator can give satisfactory and reliable results. It is best to think carefully about noise when designing a system, and especially to try to make the distance between controller and meter as large as possible.

An ultrasonic flow meter will never be immune to sonic noise, but it is manageable and no reason not to use this technology.

Photo: flow controllers with noise reduction by Fiorentini in a natural gas system.

More information?

More information about our products or looking for a custom solution?

Please contact our Sales Engineers.

NL: +31 70 413 07 00

CN: +86-(0)10-60576210

USA: +(1) 973 383 0691

TW: +886-(0)3-5600560

Already know who you're dealing with? Contact your salesperson directly:

Look up salesperson

WE MAKE YOUR TECHNOLOGY WORK

NL - Tel. +31 70 413 07 50

USA - Tel. +(1) 973 383 0691

CN - Tel. +86 (10) 56865822/56865835

TW - Tel. +886-(0)3-5600560