Turbine flowmeters for gases

Directly to:

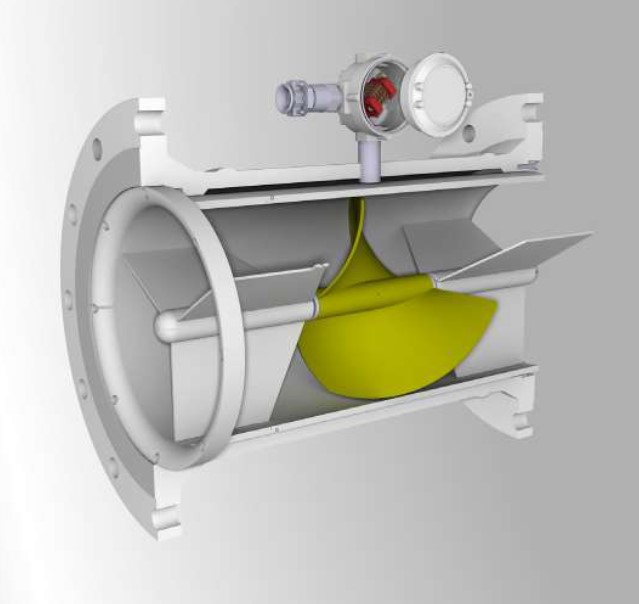

Turbine meters for gas applications

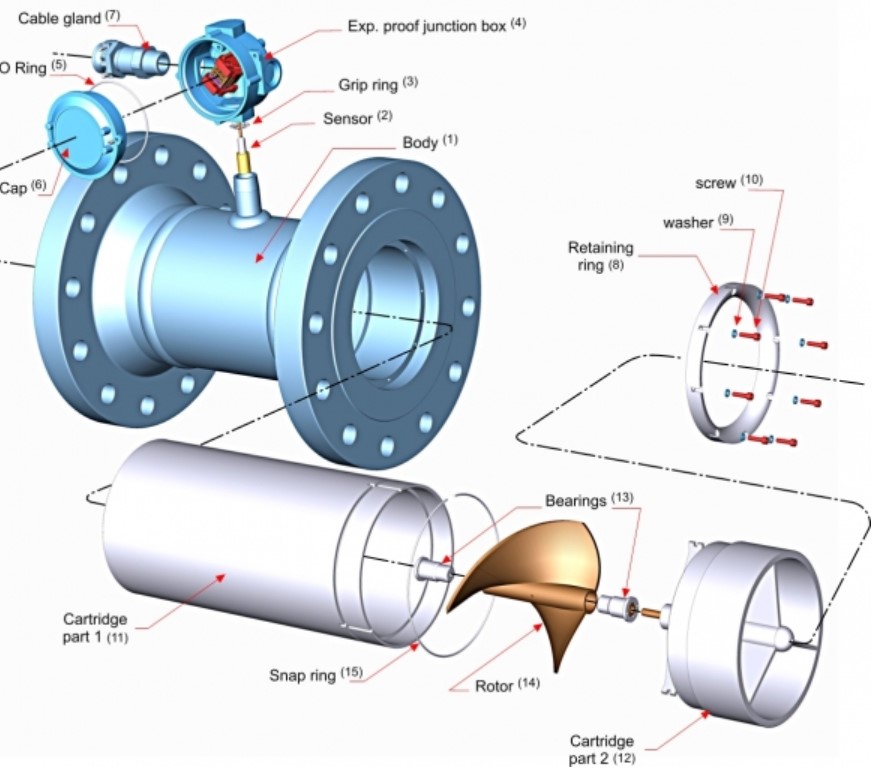

Turbine meters designed for gas applications take into account the properties of gas. Gas always has a low viscosity and is poor - a gas has no lubricating properties which the turbine bearing can take advantage of. This is why gas turbine gauges are always fitted with ball bearings lubricated with a suitable oil or the instruments are fitted with self-lubricating ball bearings. For UHP applications therefore, turbine flowmeters are almost never used.

As the gas flows through the turbine flow meter, it has some friction on the inlet pieces, the built-in flow conditioners, and also on the turbine itself. The viscosity therefore has an important effect on the performance of such an instrument. During the calibration of turbine flowmeters the Reynolds number as it occurs in the application is taken into account.

Applications

For gas applications, the turbine flowmeter is still the most accurate instrument in larger pipelines. Ultrasonic flowmeters are increasingly being used for custody transfer, high pressure applications.

Stability of the flow

Another important factor that affects the performance of this flowmeter is the stability of the flow. If the flow suddenly varies or is stopped, the turbine will continue to turn for a while. This means that there is flow measured where there is none. If the flow suddenly increases, a similar effect occurs: the turbine will always follow the pace of the flow with a delay. In case of pulsating or strongly fluctuating flow, the choice for a turbine flow meter is not the best choice and other measurement techniques are better suited.

Downloads

More information?

More information about our products or looking for a custom solution?

Please contact our Sales Engineers.

NL: +31 70 413 07 00

CN: +86-(0)10-60576210

USA: +(1) 973 383 0691

TW: +886-(0)3-5600560

Already know who you're dealing with? Contact your salesperson directly:

Look up salesperson

Any Questions?

More information about our products, services or looking for a custom solution?

Please contact our Sales Engineers.

WE MAKE YOUR TECHNOLOGY WORK

NL - Tel. +31 70 413 07 50

USA - Tel. +(1) 973 383 0691

CN - Tel. +86 (10) 56865822/56865835

TW - Tel. +886-(0)3-5600560