Orifice plates in differential pressure flowmeters

A comprehensive guide to the most used types of orifice plates.

Differential pressure flowmeters with an orifice plate as flow element are one of the most economical devices for measuring flow. Its design, sizing, and installation requirements are prescribed in ISO-5167-1 and ISO-5167-2. So as opposed to some other differential pressure measurement elements, the orifice plate has a calculated accuracy and there’s no need for calibration or re-calibration. Orifice plates are used for both fluids and gases.

We supply our customers with:

• standard or custom size orifice plates

• orifice carriers for hot swap capabilities

• flange assemblies [link naar Orifice Flanges pagina]

• customized and pre-assembled meter runs

• multi-stage restriction plate assemblies

We often integrate orifice plates to a complete meter run assembly because the ISO 5167 standard also prescribes tapping locations and upstream and downstream straight pipe lengths.

Design considerations for orifice plates

When choosing your dP flow measuring element, take these factors into consideration:

1. Flow range (also known as turn down)

2. Pressure and Temperature

3. Line size

4. Pressure loss

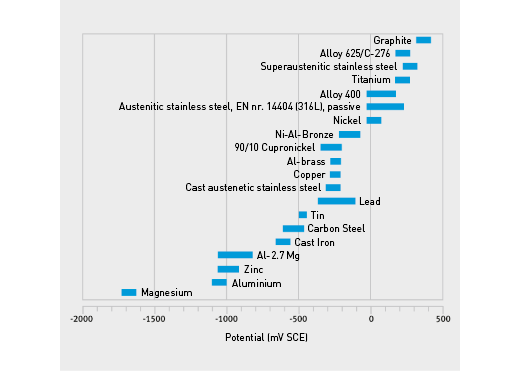

5. Medium corrosiveness

6. Medium abrasiveness

7. Location, straight lengths

8. Required performance

9. Service

We love to help you with these considerations. Together we perform a flow calculation according to ISO 5167-1 using software simulation. This gives a grip on the effect of changing parameters and can help:

• choosing the right measurement principle / flow element

• reaching a carefully considered compromise

• get a predictable measurement uncertainty

• understand whether calibration is advisable or mandatory

Orifice plate designs

Concentric orifice plates

The majority of plates used in orifice based devices are of the concentric design. The bore is sharp-edged on the inlet and parallel or chamfered on the outlet of the plate. This results in a better defined flow profile on the exit of the instrument.

Eccentric orifice plates

Concentric orifice plates are not suitable for dirty fluids, because dirt can accumulate against the plate. Eccentric and segmental orifice plates are designed such that solids can pass through the bore. [illustratie] [link naar stoom applicatie] The same is the case for condensate, when measuring wet gases like steam.

Segmental orifice plates

These type of orifice plates often have a conical or quarter-circle type aperture. Useful when measuring liquids which have a high viscosity and a low velocity. Especially in even more extreme conditions as with eccentric orifice plates. A disadvantage is that this type is not prescribed in the ISO-5167, which makes calibration necessary. Another type of flow measurement may be the better solution.

Restriction orifice plates and multi-stage plates

Orifice plates are sometimes designed to fit between flanges that have ring-type joints (RTJ). The cross section profile of the plate is designed to fit inside the recess of the RTJ flanges and is used as flange sealing. [illustratie]

PVDF coupling

Aluminium coupling

The specifications of orifice plates

The standard materials used (by our manufacturer SEIKO) for orifice plates is stainless steel according to ASME A240 316/316L. Other materials can be used as well including Duplex Steel and ASME A182 F91.

The plate thickness is selected based on the application and design conditions, typically between 3 mm (0,12 inch) to 10 mm (0,4 inch).

The flow calculation is performed according to the ISO 5167- Part1, Teesing uses Conval for that purpose. [vraag: wordt de uitkomst van de berekeningen gedeeld met de klant, of alleen de tekening? Geeft de klant akkoord op de berekening/tekening voor bestelling?]

The typical uncertainty of uncalibrated orifice plates is +/-0,5%.

The generated differential pressure is needed to measure flow, but is in itself unwanted. A part of the pressure loss however is regained after a certain amount of pipe length. The actual permanent loss depends on the Beta-ratio and is typically 45-90% of the differential pressure. The lowest possible permanent pressure loss is obtained with a venturi flow element. [link naar uitleg open area ratio, Beta]

Typical applications

When the use of a differential pressure flowmeter is preferred or mandatory, an orifice plate is the flow element of choice when the following conditions are met:

• Clean fluids (under abrasive conditions a nozzle flow element performs better)

• Non-corrosive fluids

• Sufficient straight inlet pipe section is available

• A higher pressure loss is acceptable

• Cost is an important factor (CAPEX), OPEX is actually quite good

When is an orifice plate not the right choice?

Some applications have conditions that demand another type of flow element. A few examples of such cases:

• For lowest possible pressure drop choose venturi.

• Choose a venturi cone, when low pressure drop is important, but not crucial and venturi is above budget.

• When your medium has solids in a liquid to be measured or a lot of condensate in gas (wet steam), the orifice plate will deteriorate due to erosion. The better choice is a venturi or nozzle flow element or a different flow measurement technique.

meer informatie?

Neem vrijblijvend contact op met onze specialisten:

NL: +31 70 413 07 00

CN: +86-(0)10-60576210

USA: +(1) 973 383 0691

TW: +886-(0)3-5600560

Any Questions?

More information about our products, services or looking for a custom solution?

Please contact our Sales Engineers.

WE MAKE YOUR TECHNOLOGY WORK

NL - Tel. +31 70 413 07 50

USA - Tel. +(1) 973 383 0691

CN - Tel. +86 (10) 56865822/56865835

TW - Tel. +886-(0)3-5600560